Pioneering Progress

Unleashing the full potential of innovation to make life more comfortable, healthier, and smarter. FXI is constantly developing new solutions, technologies and applications that redefine what’s possible.

Research and Development

FXI’s track record for innovation in unparalleled in the industry. Our Research and Development (R&D) function is fully integrated with our manufacturing organization to optimize the efficiency and reliability of our innovation pipeline. We are dedicated to understanding consumer needs and market trends alongside of R&D and technology innovation. This has resulted in the creation of proprietary solutions that not only meet the needs of today but also exceed the needs of tomorrow. Come visit our main R&D center, located in Aston, Pennsylvania and see how we are developing innovation you can feel.

INNOVATION STORIES

A quieter ride

Our automotive insulation foams do a lot more than cushion passengers. Not only do they make cars safer and more comfortable, they also dramatically reduce engine and exterior noise with superior sound attenuation, making every ride smoother and more relaxing.

A fresher world

FXI is driving a great leap in the efficiency of air purification systems. Our new photocatalytic filter technology will help clean, sterilize and deodorize air and water better than existing methods. As air filter manufacturers, we're making more places fresher and healthier for everyone.

A safer procedure

More and more, medical foams play a vital role in modern medicine. Our "de-foaming" technology allows blood oxygenators and other surgical devices to oxygenate blood during heart surgery without creating dangerous air bubbles. This results in better practices and longer lives.

A more colorful workplace

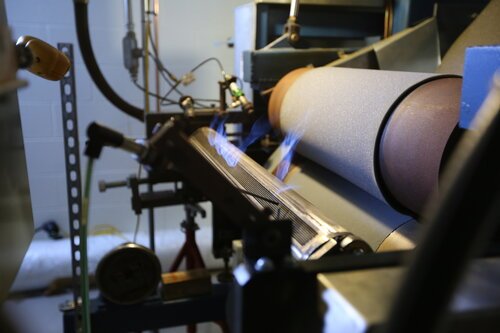

Without foam, printing innovations in affordable color digital imaging technology wouldn't be possible. Our foam technology transports ink without clogging or pooling, so today's printers can deliver perfect results every time. Making every day a little brighter.

A safer finish

Perfected over 30 years in jet aircraft, fuel cell foam technology now plays a critical role in protecting all types of vehicles. Our safety foam is used in today's stock cars to help mitigate fuel explosions ensuring a safer racetrack for drivers and fans.

Less pressure

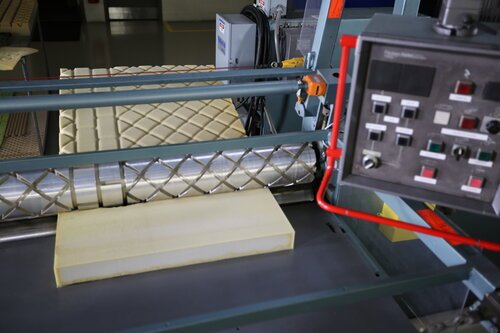

FXI is at the forefront of research and innovation in the support surface industry, expanding the boundaries of performance in polyurethane foams. With more than 40 years of research and development and over 200 patents, FXI is the industry leader in medical mattress innovation.

A greener, cleaner world

Our Variable Pressure Foaming (VPF™) technology is the only of its kind in the polyurethane foam industry. We are committed to making the world a cleaner, greener place with our eco-friendly foam.

PROCESSES

From chemical and polymer characterization to physical, foam and textile testing, FXI offers a comprehensive range of material testing services. No matter the material or application, we can ensure the right requirements and highest standards are met in our materials testing laboratory.

TESTING SERVICES

From chemical and polymer characterization to physical, foam and textile testing, FXI offers a comprehensive range of material testing services. No matter the material or application, we can ensure the right requirements and highest standards are met in our materials testing laboratory.

CHEMICAL CHARACTERIZATION

Gas Chromatography-Mass Spectrometry (GC-MS)

Infrared Spectroscopy (IR)

Nuclear Magnetic Resonance Spectroscopy (NMR)

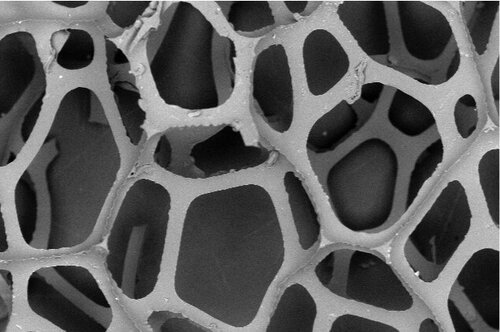

Scanning Electron Microscopy-Energy Dispersive X-ray Spectroscopy (SEM-EDX)

POLYMER CHARACTERIZATION

Gel Permeation Chromatography (GPC)

Dynamic Mechanical Analysis (DMA)

Differential Scanning Calorimetry (DSC)

Thermogravimetric Analysis (TGA)

PHYSICAL TESTS

Density

Tensile Strength

Elongation at Break

Tear Strength

Flammability Testing

Environmental Testing (Temperature, UV, Humidity)

Electrical Resistivity

Acoustical Testing (Transmission Loss and Absorption)

Pressure Mapping

FOAM TESTS

Pore Size

RAM

Visual

Pressure Drop

Permeability

Indentation Force Deflection (IFD)

Compression Force Deflection (CFD)

Static and Dynamic Fatigue

Loaded Height

Low Temperature Flexibility

Low Temperature Load Compression

Migratory Staining

Mildew

Odor

Porosity (Dow, Frazier)

Resistance to Blocking

Resistance to Heat Aging

Resistance to Humidity

Retained Tensile Strength

Seam Fatigue Resistance

Seam Strength

Shrinkage

Solvent Resistance

Specular Gloss

Stain Protector Performance (Oil, Water)

Stain Release

Static Force Loss

Static Friction

Steam Autoclave Aging

Steaming

Stretch and Set

Taber Abrasion

Tear Strength (Tongue, Trapezoid, Trouser)

Tensile Strength

Thickness

Visual Evaluation of Automotive Trim

Water Spotting

Weight

Wicking

Width

Xenon Arc Weatherometer

Yarn Count

FABRIC/TEXTILES TESTING

Antimicrobial Milk Test

Ash Content

Ball Rebound

Bond/Peel Strength

Bow & Skew

Cleanability

Cleaning Resistance

Cold Cracking

Color Crocking

Colorfastness to Elevated Temperature

Colorfastness to Light

Compatibility

Compression Force Deflection (CFD)

Compression Set

Crease Resistance

Curling

Cycle Aging

Density

Dimensional Stability

Dry Heat Oven Aging

Elongation

Fastening Strength

Fiber Degradation

Firmness

Oil Repellency

Water Repellency

Flammability

Flex Fold

Flex Fatigue

Flexibility

Fogging

Hydrolytic Stability

Indentation Force Deflection (IFD)

Indentation Residual Gage Load (IRGL)

Laminate Curl