Processes

Reticulation

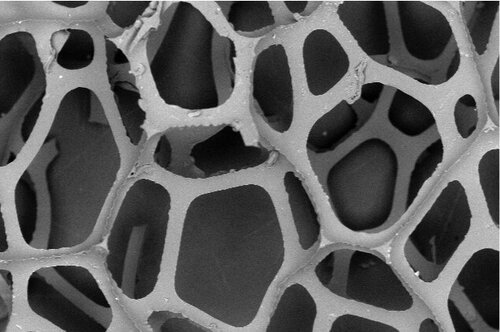

In reticulated solutions, the cell membranes are removed during the manufacturing process to allow for low flow restriction. The struts remain to form the structure and a tortuous path for the air and dust particles to flow into.

STRUCTURE OF POLYURETHANE SOLUTIONS

Our products are made up of dodecahedron cells. The walls of these cells are constructed of struts and membranes that stretch between the struts. These struts vary in diameter depending upon the density of the product. The membranes (or windows) are very thin and can be ruptured depending on needs.

USES OF RETICULATED SOLUTIONS

Reticulated products are ideal for filtration purposes, as it has low flow restriction and an intact structure.

In reticulated polyurethane foam, the cell membranes are removed during the polyurethane manufacturing process to allow for low flow restriction. The struts remain to form the foam structure and a tortuous path for the air and dust particles to flow into. As the air flows into the cell structure, dust is trapped within the dodecahedron cells of the reticulated foam.

FOAM RETICULATION PROCESSES

Reticulated polyurethane foam is created by removing cell membranes through one of two methods in the polyurethane manufacturing process.

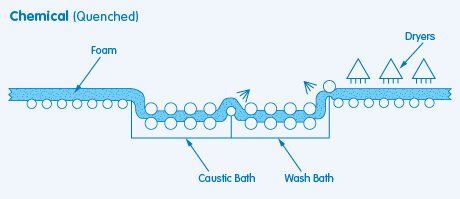

The first method is via chemical etching or quenching (Figure 1), and consists of passing the polyurethane foam through a caustic bath at a controlled concentration, temperature and speed. The quenching process etches away the thin membranes between the struts, and the final product is a completely open foam structure which we call reticulated foam. The surfaces of the remaining struts are rough from etching, which makes the quenching process ideal for polyester-based reticulated polyurethane foam.

The second method is called thermal reticulation (Figure 2). Thermal reticulation takes place in a pressure vessel capable of withstanding the ignition of a mixture of hydrogen and oxygen gases. Polyurethane foam is placed in the vessel, a vacuum is created inside, and an explosive mixture of hydrogen and oxygen gases is introduced into the vessel. When the proper charge is obtained, an ignition source is activated which causes a flame front to pass through the foam at sub sonic speed, burning the polyurethane foam membranes. The thermal reticulation process also yields windowless reticulated polyurethane foam, but thermally reticulated foam features a flame-polished surface on its struts.

The process can be performed on all three polyol-based polyurethane foams (Ether, Ester and Polymer Polyol). Thermally reticulated foam yields slightly lower pressure drop values for a given air flow than chemically quenched foam.